This is called two-blocking and can cause injury or death as well as damage to the crane load line and ball or block. These systems are designed to work on telescopic cranes boom trucks derrick trucks and conventional lattice cranes.

Two-blocking is a dangerous condition where the hook block is raised until it contacts the boom tip.

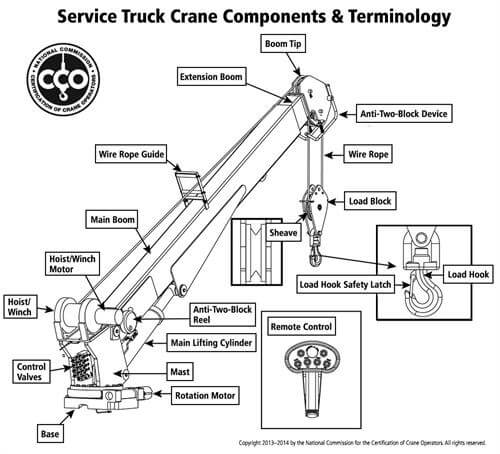

Anti two blocking device on cranes. B Lattice boom cranes shall be equipped with an anti-two block device or a two-block warning feature that functions for all points of two-blocking. Having an anti-two blocking device will ensure the safety of workers which gives them a sense of security and in turn leads to increased productivity and efficiency at work. Anti two-blocking devices are electrical sensing devices.

They are installed on the crane to prevent the headache ball from hitting the sheave. If such contact causes the line to break the man basket can tip or fall. The anti two-blocking device consists of a weighted ring around the hoist line.

The ring is suspended on a chain from a limit switch that is attached to the boom tip. Anti two block ATB or A2B warning systems are used to warn or prevent the crane operator from two-blocking the crane. Two-blocking is a dangerous condition where the hook block is raised until it contacts the boom tip.

Without a proper crane A2B system a two-block can cause expensive damage to the crane boom personnel and surrounding property. The systems developed in the 30s and 40s include more advanced indicator switches switch control mechanisms limit switches cable safeguards means of measuring loads and other devices to prevent anti-two block related crane accidents. Bode Technical Services specializes in crane repair of electronic control systems on all major crane brands.

BTS is a wordwide supplier of crane parts including PAT. The anti-two-blocking device as is utilized on the 9270 crane has been destroyed twice by its inadequate design which does not preclude the counterweight from being entangled in the hoisting line thereby severing the attachment cable or chain and free falling to the headache ball at which time it self destructs and spews the area with metal shrapnel. An Anti Two Block Warning System is an integral safety device for your crane.

The system helps prevent the crane operator from having a two-block accident. This is where the cranes hook block is raised to a height where it comes into contact with the boom tip. This precarious situation can cause the cranes boom to bend and to break the hoist line.

The code states that there are exceptions to the Anti-Two-Block requirement. The Exceptions are listed below and can be found in the following Federal OSHA New Crane Rule 19261416d3iiC. Anti-Two-Block Protection should not be used during the following operations.

Dragline Clamshell grapple Magnet. 5263660 issued on Nov. 23 1993 to J.

Brozik teaches another anti-two blocking device for preventing a lower load block on a crane from coming into contact with an upper load block. The device includes a cable follower through which the cranes cable is threaded and situated between the upper load block and the lower load block. To prevent the backhoe or crane from striking or crushing employees always barricade areas within the swing radius of the rear of the cranes rotating superstructure.

This barrier can consist of orange reflective traffic cones or barrels which marks and warns both the crew members and the uninformed public of the dangers of these machines. Also there either was no A2B anti-two-block system on the crane or it was defective and had not been tested at the beginning of the shift. This safety device when functioning properly will prevent the hook from being pulled into the boom tip.

If you inadvertently two-block the crane be sure to thoroughly inspect the hoist line for damage. Crane rigging Anti Two Block - YouTube. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features.

2021 Google LLC. An anti two-blocking device for preventing a lower load block 46 on a crane 10 from coming in contact with an upper load block 44 affixed adjacent a boom point 40. The device comprises a.

3 Anti two-blocking device. I Telescopic boom cranes manufactured after February 28 1992 must be equipped with a device which automatically prevents damage from contact between the load block overhaul ball or similar component and the boom tip or fixed upper block or similar component. 19261416d3i Telescopic boom cranes manufactured after February 28 1992 must be equipped with a device which automatically prevents damage from contact between the load block overhaul ball or similar component and the boom tip or fixed upper block.

Anti two-block or ATB systems help prevent the ball block from contacting the boom tip. This is called two-blocking and can cause injury or death as well as damage to the crane load line and ball or block. The Altec ATB system consists of a load line weight suspended from a chain connected to a.

Anti two-blocking devices are electrical sensing devices. They are installed on the crane to prevent the headache ball from hitting the sheave. If such contact causes the line to break the man basket can tip or fall.

The anti two-blocking device consists of a weighted ring around the hoist line. The ring is suspended on a chain from a limit switch that is attached to the boom tip. A crane assembly includes an anti-two block system having a rigid body a sensor configured to detect upward loading of the body and a spring biasing the body to a pin of a sheave.

The body includes a base two extensions projecting perpendicularly upward from the base and extending outside the sheave on opposite sides thereof and a fitting on upper ends of the extensions. An anti two-blocking device for preventing a lower load block 46 on a crane 10 from coming in contact with an upper load block 44 affixed adjacent a boom point 40. The device comprises a cable follower 60 through which the cranes cable 26 is threaded situated between the upper load block 44 and the lower load block 46.

Each Seatrax pedestal crane is equipped with a patented mechanical anti-two blocking system to remedy offshore crane operations accidents caused by the unintentional contact between the hook block or ball and the boom point often referred to as two-blocking. One type of two-blocking often described as booming down into the block occurs on most cranes because of the location of the hoist drum. The crane replacement anti two block system are a series of devices designed to warn the operator of an impending two block situation and shut off crane motion via pre installed shutoff solenoids.

These systems are designed to work on telescopic cranes boom trucks derrick trucks and conventional lattice cranes. Two blocking means a condition in which a component that is uppermost on the hoist line such as the load block hook block overhaul ball or similar component comes in contact with the boom tip fixed upper block or similar component. This binds the system and continued application of power can cause failure of the hoist rope or other componentToo often we see mobile cranes missing anti-two blocking devices.

Peralatan keselamatan hook overwind preventive device atau sering juga disebut dengan anti toe block merupakan peralatan keselamatan yang berfungsi untuk mencegah hook pada crane bergerak terlalu ke atas yang berpotensi menyebabkan benturan antara hook block.